Sebenza neHorsent namuhla ukuze ulondoloze

Umnyango wokukhiqiza amahhashi Ubhekele ukuphathwa okuphakathi kwenqubo yokukhiqiza isikrini esithintwayo;

Inqubo ngayinye yokukhiqiza izosebenzisa amathuluzi afanelekile kanye nemishini yokuqapha neyokulinganisa elinganiselwe;Ukulebula nokugcina imikhiqizo ukuze kuqinisekiswe ukulandeleka;Hlela umkhiqizo ngokohlelo lokukhiqiza.

Ulayini wethu womkhiqizo wekilasi Lokuqala uyakwazi ukukhiqiza iziqapha zesikrini sokuthinta futhi konke ngamasethi angu-210,000 ngonyaka.

Sibuyekeza inqubo yokusebenza ejwayelekile(SOP) noma nini lapho kunenkinga, ukuthuthukiswa noma ukungabaza.

Ukugijima ngokumelene ne-SOP ukuhlangabezana nesivinini sokukhiqiza kuphambene namagugu ethu.

Ukusuka Ekuhlanganiseni kwephaneli yokuthinta, ukuhlanganisa uhlaka, ukuya ku-PCB, i-LCD eshumekiwe, ukufakwa kwepuleti nezindlu kanye nokuguga

Olayini bethu baphathwe ngokwe-ISO9001-2015, njengabakhiqizayo, abaphumelelayo, abanokuncintisana, abaphephile futhi abakhulu.

Ukuhlanganisa Iphaneli Yokuthinta.

Amahhashi asebenzisa amateyipu angu-3M ukuze ahlanganise iphaneli yesikrini esithintwayo.

Ngaphambi kwalokho, sihlole futhi saqinisekisa umthamo nokunamathela kwamateyipu nokuthi angakwazi yini ukumelana nezikhathi ezengeziwe zokuqapha ezinhlelweni zokusebenza zezikrini zokuthinta zangempela.

Sisebenzisa izigaba ezihlukene zephaneli yokuthinta ngayinye ehlukene kanye nosayizi wokuqapha, ngisho nokugcwaliswa kwegebe okuhlukile futhi siqinisekisa ukusetshenziswa kwetheyiphu ehambisanayo kulo lonke uhlobo lomkhiqizo wethu.

Ihhashi elilinganiswe namateyipu kanye nokotini wokuphefumula, okunamathelayo okuqinile kusangenisa umoya ukwakheka kwephaneli yesikrini esithintwayo ku-LCD ukuze kugwenywe ukuminyana.

Ukuhlanganiswa kwe-LCD

UHorsent ungumnikazi wegumbi elihlanzekile elingu-20m2 elinempahla egcwele kanye nezinsiza ze-LCDIphaneli yokuthintaukuhlangana.

4 Iziteshi zokusebenzela emakamelweni ahlanzekile okuhlanganisa + nokuhlanza izintuli, nesiteshi esisodwa sokuhlanza okokugcina ngemva kokuhlanganisa.

Umnyango wethu wobunjiniyela uhlola futhi uhlole amathuluzi nezinsiza ezifana nokugeleza komoya, ukuvunguza komoya nendawo yamazinga okushisa nomswakama njalo

ukuqinisekisa indawo ehlanzekile nebalulekile kanye nokusebenza okushelelayo kwe-LCD nangaphakathi kwemonitha yesikrini esithintwayo.

Ekugcineni, i-Horsent ifinyelela igumbi lokuhlanza elijwayelekile le-6S lokukhiqiza okuphephile nokukhiqizayo.

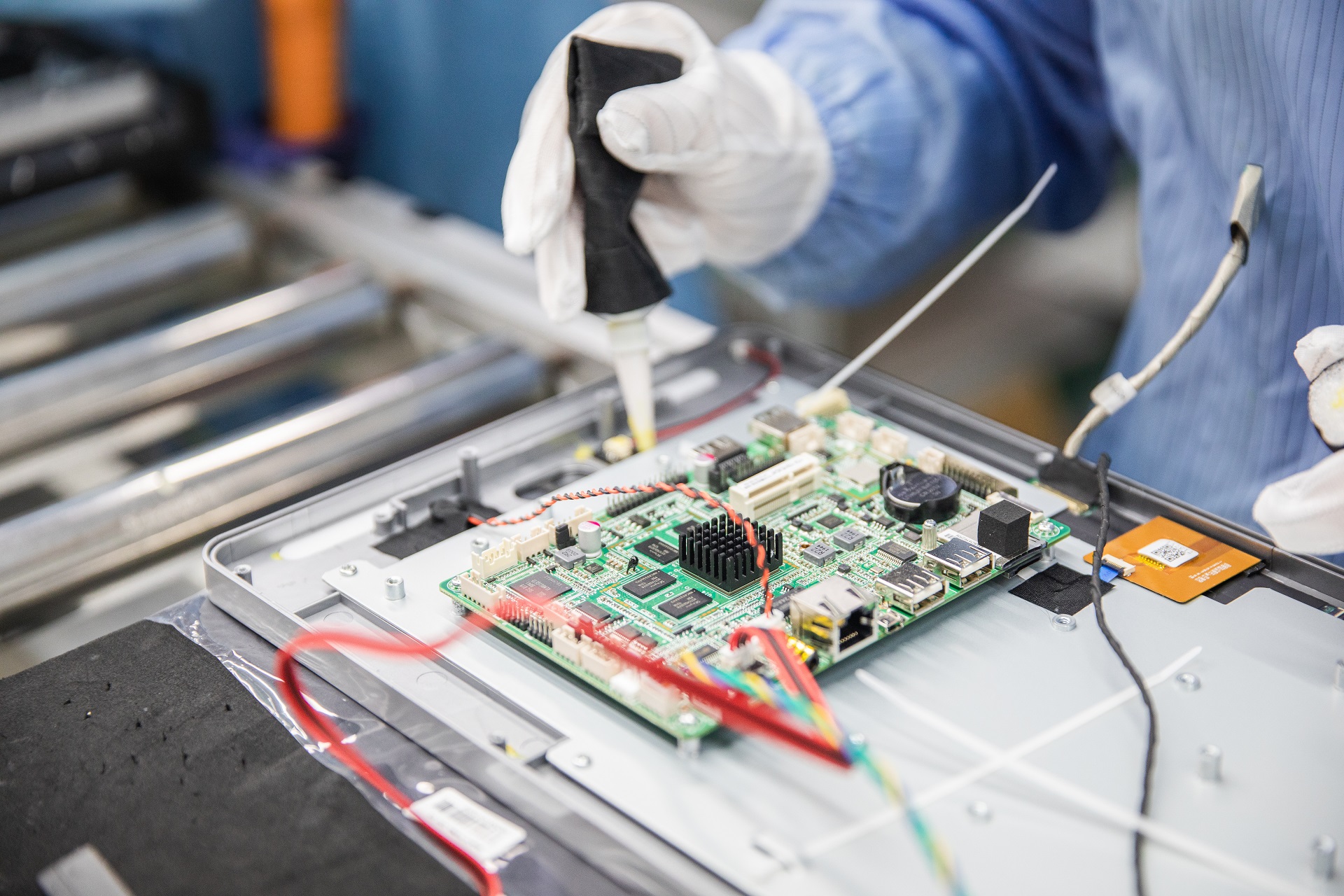

Ukuhlanganiswa kwe-PCB

I-Horsent inezindawo zokusebenza eziyi-8 zokuhlanganisa i-PCB, okuhlanganisa Ibhodi le-AD, ibhodi yesilawuli sesikrini esithintwayo, nama-PCB wezikrini zokuthinta konke endaweni eyodwa.

I-PCB ngayinye iphethwe ngaphansi kwamasistimu kokubili inqubo yesistimu ye-inthanethi kanye nokwehla, ukuze kuqinisekiswe ukulandelwa okugcwele kwe-PCB ngayinye nokufakwa kwayo.

Ophiko lobunjiniyela bahlola amathuluzi nezinsiza njalo ukuze baqinisekise ukusebenza okuphephile nokusebenza kahle.

Ukufakwa kwezakhiwo

I-Horsent isetha izindawo zokusebenza eziyi-8 zokufakwa Kwezakhiwo

okuhlanganisa amapulani, ozimele, nezindlu...kokubili izikrini zokuthinta ezinozimele ovulekile neziqapha isikrini esithintwayo.

ukuze uzuze izakhiwo eziqinile ngaphakathi kwemonitha yesikrini esithintwayo ukuze usebenze kahle, isikhala esicebile somoya nokushisa.

ngaphandle, i-Horsent izimisele ukwakha i-casing ephephile nehlala isikhathi eside kanye nendlu ukuze ivikele isikrini esithintwayo ekushiseni, othulini namandla.

Ukwelapha & Ageing

Ukuze kuzuzwe ukuchayeka kwangaphambi kwesikhathi kodaba kanye nomkhiqizo we-NG, ongena emakethe, u-Horsent wakha igumbi elizimele elingu-60m2 lokwelapha nokuguga kwawo wonke amamonitha wezikrini zokuthinta kanye nesikrini esithintwayo konke ngakunye.

Amahora angu-4~8 okwelapha azodalula amandla amaningi kanye nezingozi zomkhiqizo wethu ngaphambi kokuhlolwa kokubona nemisebenzi.

Hlola ubunjiniyela bamahhashi futhi uqinisekise ukuthi indawo yegumbi lokuphulukisa iseduze nendawo yangempela yezinhlelo zokusebenza zesikrini esithintwayo.